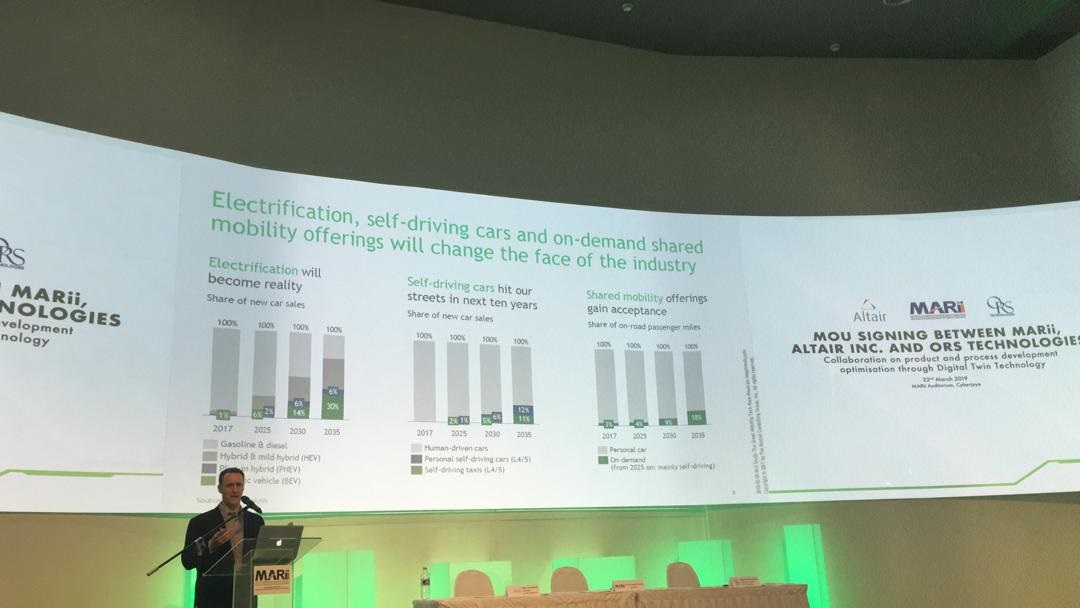

Altair Engineering President, Brett Chouinard presented about the shared mobility industry, during the MoU signing event at MARii HQ in Cyberjaya.

Altair, a software development company that provides solutions in the areas of product development, high performance computing (HPC) and data intelligence, has signed a memorandum of understanding with the Malaysia Automotive Robotics and IoT Institute (MARii).

The tripartite agreement with ORS Technologies (ORS), will see all three parties combining their expertise in market insights, engineering solutions, automotive design technology, training and consultation, in the area of Digital Twin technologies for Malaysia and regional markets.

Digital Twin technologies

In essence, Digital Twin technologies are applied to super high-value assets which are equipped with sensors to record data, make sense of the data, and then feed insights from these data, back into the system.

While all of this happens, it should be noted that a digital twin is meant to exactly replicate reality at any given time; in other words a digital twin is an accurate digital representation that is used to simulate situations in the real world, with the purpose of finding optimal solutions

With the added advantage of all these data transfers happening in real time, diagnosis of products, systems, and processes can be made in real time and measures to correct can be made immediately, reducing cost as a result.

More than just for automotive

MARiI CEO, Dato’ Madani Sahari said, “Digital twin (technology) has many applications like improving products as it progresses along its lifecycle, or to ‘re-engineering’ them to become better.”

He added that Digital Twin can be applied to not just the automotive industry, but can cut across to other industries as well.

Brett Chouinard, Altair Engineering President also chipped in that from a previous arrangement with MARii, Altair had been able to create through simulation, some of the digital data that represents a digital twin.

“Additionally, in order to use this ‘twin’ you need to create an infrastructure so that the data can be collected, captured, calculated and shared at different stages of a product virtual lifecycle.”

Take up

According to Altair’s MD in Asia, Srirangam R Srirangarajan, there are 100 units of Digital Twins around the world, and while they are predominantly found in the aircraft manufacturing industry, they are moving into other industries like automobile manufacturing.

They are currently being used for in-service applications for example predictive maintenance so as to reduce risk of high cost and risk to employee safety. The data collected also provides valuable feedback to product designers and overall, optimise the shop floor and manufacturing resources.

In conclusion, Dato’ Madani expressed his wish for the technology to “further enhance opportunity to help and assist the automotive and mobility industries, as well as other sectors that need to further update their technology development.”